Printed flexible heaters

DuraTech creates custom printed flexible heater solutions

Flexible heaters with printed electronics

Welcome to innovation in flexible heating elements that’s sure to redefine your brand. Unlike traditional silicone flexible heaters, our fixed resistance and PTC heaters utilize cutting-edge printed electronics for a lighter, more durable, more sustainable wearable.

Welcome to innovation in flexible heating elements that’s sure to redefine your brand. Unlike traditional silicone flexible heaters, our fixed resistance and PTC heaters utilize cutting-edge printed electronics for a lighter, more durable, more sustainable wearable.

This technology replaces fallible copper connections and wiring, eliminates the need for bulky insulation, and requires less energy to apply heat precisely and safely where it’s needed.

Powered by our patent pending flexible non-metal connector, DuraTech flexible heater solutions are easily integrated into products that require a conformable heat source.

As our abilities to print electronics become more precise and refined, the possibilities of what we can help you achieve is nearly limitless. Launch an exciting new chapter for your brand with our flexible heater solutions.

Start your custom flexible heater solution today!

DuraTech’s flexible heater offerings

Fixed resistance flexible heaters

Stretchable and conformable inks and films enable you to apply heat for comfort and therapeutic use.

Key components of fixed resistance flexible heaters:

- Flexible conformable connector: Remarkably light and practically undetectable by the end user.

- Cover film: Made of thermoplastic polyurethane (TPU), it adds a soft, elastic top layer that’s easy on the skin and conforms to the body.

- Heating element: Made of specially resistant carbon and silver printed inks.

- Busbar system: Silver conductive inks conduct electrical signals while also being stretchable and flexible.

- Base: Ultra flexible TPU film

- Fabric: Optional

Benefits of fixed resistance flexible heaters:

- Stretches and conforms

- Durable and resilient in multiple wash cycles

- Slim design; requires no bulky insulation

- Energy efficient

- Battery powered

Common industries for fixed resistance flexible heaters:

- Medical, including emergency care and physical therapy

- Military apparel

- Outdoor and athletic apparel

- Automotive

Applications for fixed resistance flexible heaters:

- Heatable clothing for outdoors and athletics

- Hot packs to treat injuries and arthritis

- Heat therapy for diabetics

- Emergency thermal blankets

- Heated sleeping bags and sleep pads

- Steering wheel heaters

- Post surgical therapeutic braces

- Anywhere heat is needed for personal or therapeutic use

Learn more about how DuraTech is shaping the frontier of flexible electronics.

PTC Flexible Heaters

These flexible printed electronics are layered on PTC, carbon and PET films. While they have the ability to flex and wrap around a curved surface, they can also integrate with rigid components.

Key components of PTC flexible heaters

- .005” PET film

- Silver conductive ink

- Carbon PTC ink

- Dielectric ink

- Self-regulating technology

Benefits of PTC flexible heaters:

- Exceptionally precise temperature control, prevents overheating

- No sparking or shorting

- Ability to flex and wrap around a curved surface

- Climate resistant and durable in outdoor conditions

- Fails to zero

Industries for PTC flexible heaters:

- Industrial

- Electronics

- Military

- Food service

Applications for PTC flexible heaters:

- Deicing and anti-condensation for mirrored or glass panels

- Food and beverage warming in commercial food service

- Process heating

- Warming of electronic displays

- Warming of lithium-ion batteries

- Anywhere surface heating is needed on either flat or curved surfaces

Ebook: A Manufacturer’s Guide to Flexible Heaters Powered by Printed Electronics

Imagine a wearable heating element that’s inconspicuous, comfortable, that flexes and flows with the fabric. This concept is not a futuristic vision; it’s here and DuraTech can help you bring it to market.

DuraTech creates human-friendly heating elements powered by innovative printed electronics. They integrate seamlessly into wearable technology and offer unparalleled design freedom for applications that require a conformable heat source.

Our flexible heating elements use revolutionary concepts in inks and films designed to stretch and conform. All-day comfort combines with safe, durable personal heating that holds up after dozens of wash cycles.

Silicone flexible heaters vs printed electronic flexible heaters

Not all flexible heaters are alike. Silicone flexible heaters have ushered new advances in heat technology for personal and industrial use. However, a quick comparison of silicone heaters to printed electronics reveals a powerful truth: The future of flexible heaters is printable.

Traditional silicone flexible heaters

- Components made of polyamide film coated with silicone, granting the unit waterproof, flexible properties.

- Copper wiring at the connector creates a weak point. Prone to breakage after long-term exposure to wear, use and vibration.

- Manufacturing and refining of copper materials causes environmental harms.

Printed electronic flexible heaters

- Made of thin film and electronic printing of silver inks with capabilities to stretch, conform and wrap.

- Silver inks printed on flexible material offer exceptional durability and flexibility, eliminating the issues of breakage that occur in silicone flexible heaters.

- Sustainable. No acid stripping or other environmentally harmful processes required in production of cavitated silver inks.

Technology partnership with ACI

DuraTech is proud to partner with ACI Materials to bring unrivaled innovations in flexible heating that will bring your offerings to the next level. Through our partnership, we have access to their expertise and advanced innovations. As you’re bringing your flexible heater powered product to market, you’ll have access to the best of the best in additive manufacturing concepts and practices.

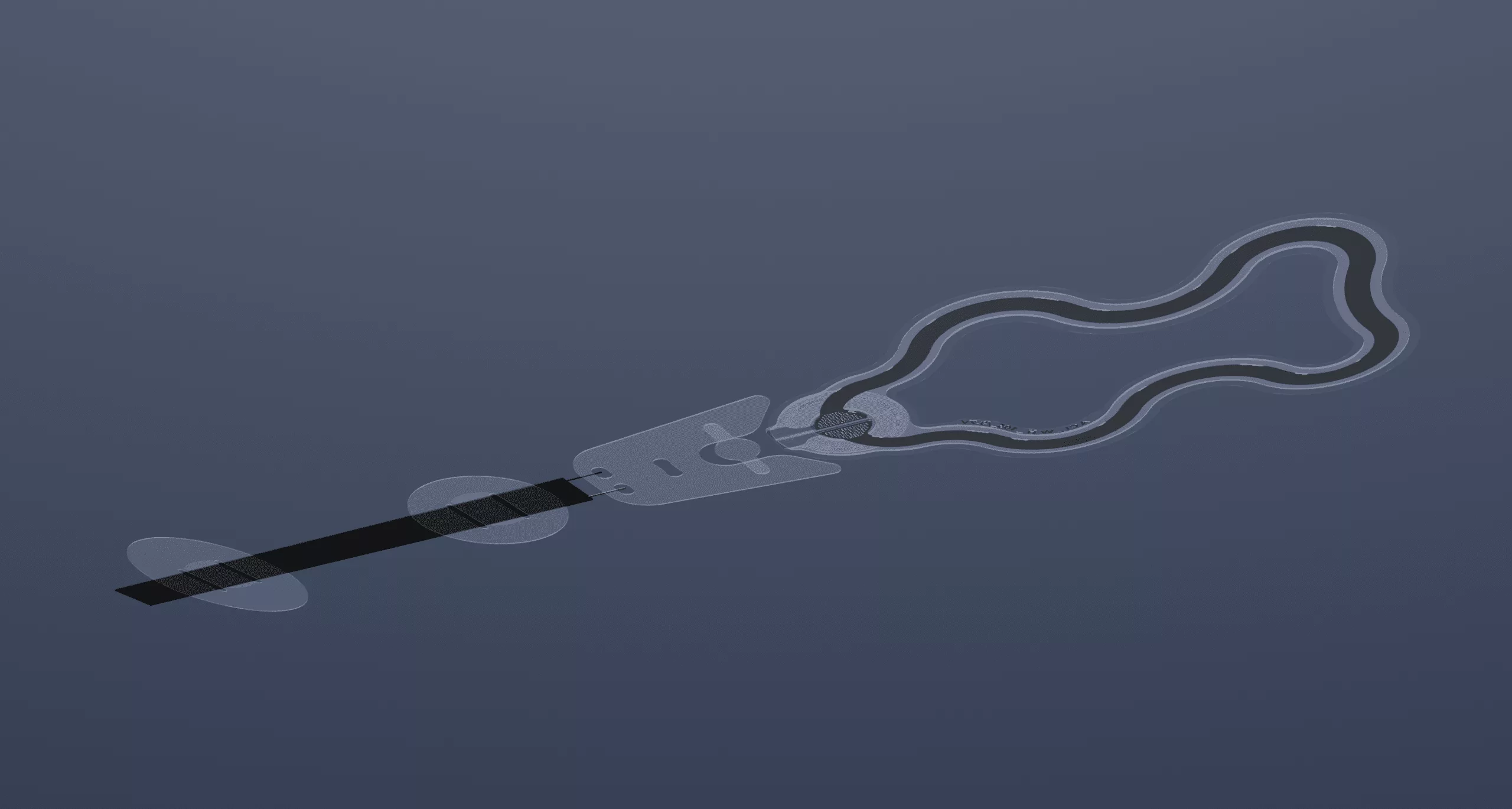

The DuraTech Difference: D-Bit Connector

When it comes to sourcing heating elements for your product, the connector is a critical component, as it delivers current to the heater. Because it’s often made of hard, bulky materials, it can be a source of discomfort to the end user.

However, our D-Bit Connector is different. It’s designed to be conformable. Developed in a partnership between DuraTech and ACI, this power connector paves the way to innovations in applying heat in medical and therapeutic settings. (Patent is pending.)

The world’s thinnest connector: With the thickness of nearly two human hairs, the D-Bit Connector is light and flexible enough to integrate with fabric, while being imperceptible to the person using it.

Robust power source: The D-Bit Connector is equipped to deliver up to three amps of power.

Innovative: This technology uses ACI Materials Alchemy Series Inks, atmospheric correction and waterproof construction while maintaining an extremely low junction heat signature.

That’s how DuraTech delivers exceptional comfort and functionality in its flexible heating elements.

Why work with DuraTech Industries?

At DuraTech we look forward to helping you redefine your industry with our cutting-edge electronic printing solutions.

But we don’t stop there. Our people make the difference. From prototyping to manufacturing, our technical team is focused on identifying the most efficient but effective means to customize your flexible heater. In as little as two to three weeks, we can produce a finished design.

Our innovation and our people are a powerful combination. Let us bring your vision for better, safer heating into reality.