DuraTech Industries – Bangor Division Relocates to La Crosse, WI Headquarters

In 2003, DuraTech acquired a company called, “Photo Art Techniques,” located in Bangor Wisconsin, which offered unique capabilities for Metalphoto® and sublimation. It was later renamed, “DuraTech Industries-Bangor Division.” In late 2020, the DuraTech Industries-Bangor Division closed, and reopened at the DuraTech Industries-La Crosse, WI Plant and Headquarters.

The former Bangor Division, now called, the “Metal Photo/Dye Sublimation Department,” is open and fully operational in La Crosse. It continues to offer the same services, including, Metalphoto® (photo image on metal) and sublimation, which is a full color process printed on substrates such a metal, plaques, mugs, awards, and t-shirts. The department’s Senior Technician, Mariann Souchek, who was with the Bangor Division prior to moving to La Crosse, provides years of expertise with these processes. The department is led by Kurt Scharping, who is also DuraTech’s Ink Mixing Department Team Lead.

According to Scharping and Souchek, the Metalphoto® process was brought to Bangor back in the early 1980’s. Over the years the process remains the same, with the following steps:

- A special photo sensitive material is used to expose a customer specified image on it.

- The material is then ran through a developer and fixer to make the image appear and remove unwanted coating from the material.

- The material is then rinsed and placed in a sealing tank. The sealing process makes the product resistant to water and chemicals.

- Nameplates are then individually cut and the corner radius can be trimmed if they are customer specified.

Sharping said DuraTech offers metal in different thicknesses, as well as a gloss or satin finish. The metal can also be tinted before sealing in gold, antique bronze, copper, or can remain simply silver. Metalphoto® products have the outdoor durability of 20 plus years. They are resistant to chemicals, abrasion, and heat, solvents and UV/sunlight.

Applications for Metalphoto®

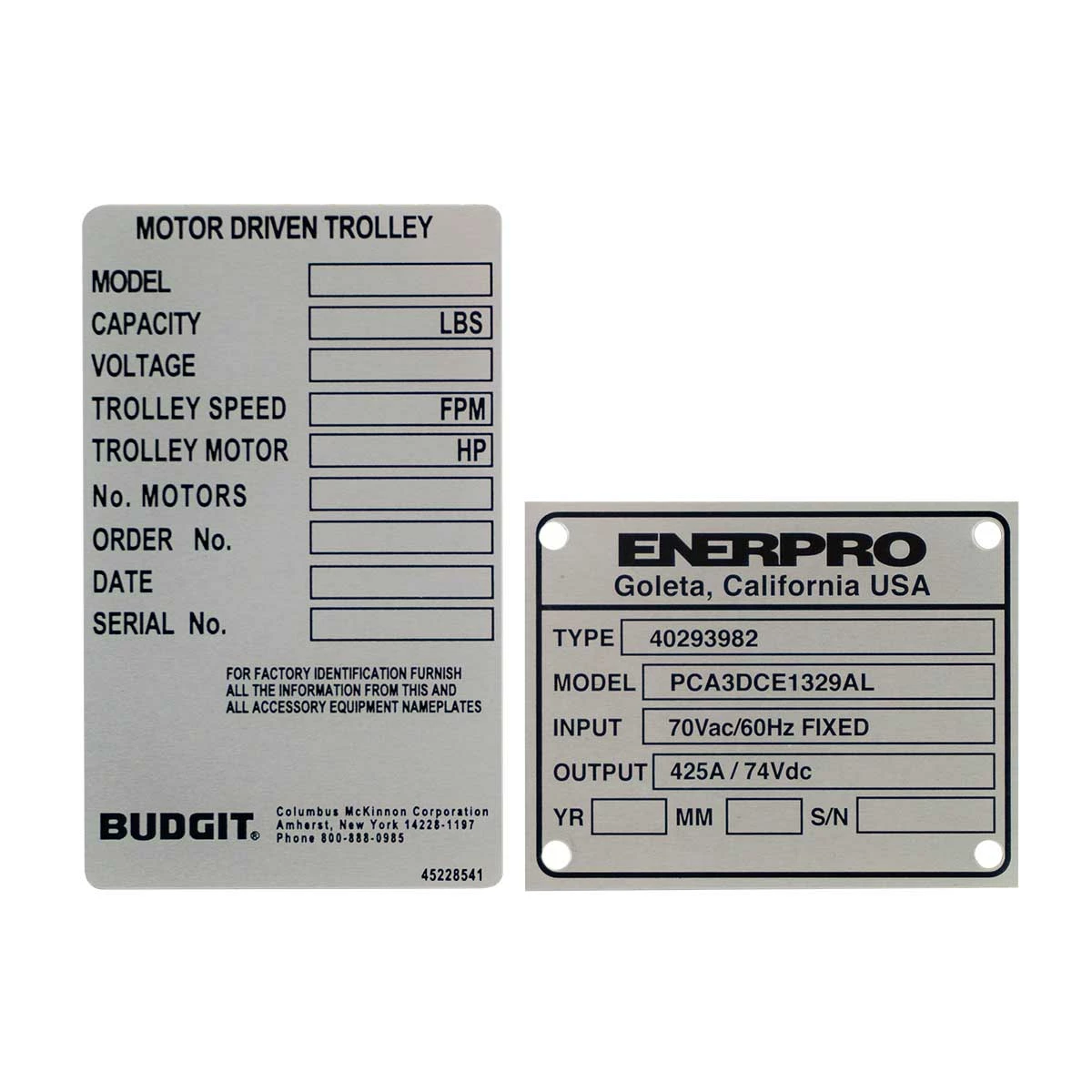

- Nameplates

- Panel Fronts

- Bar Code Labels

- Data Plates

- I.D. Asset Tags

- Signs

- Wiring Diagrams and Schematics

- Plaques and Awards

The Dye Sublimation process is a more cost effective solution to having graphics done on metal, but it does not have the outdoor life that Metalphoto® offers. The dye sublimation process is achieved by using Art files to print graphics on special transfer paper.

- The dye sub printer uses a four color process system to achieve colors that are created in the artwork.

- The transfer paper is then placed on a special coated material that is designed for the dye sublimation process.

- It is then placed in a heat press to transfer the inks from the transfer paper to the metal or whatever material being used

Souchek said she has performed the dye sublimation process with the following:

- Aluminum – White, Gold, and Silver

- Specially treated wood

- Ceramic Tiles

- Can Koozies

- Acrylic

- Keychains

Many plaques have been processed through this department over the years, and will still be a product offering. Both Metalphoto® and dye sublimation metals are used on the plaques. Scharping explains that an adhesive is used to apply the metal nameplates to the plaques and decorative brass nails are added to each corner of the nameplate to give them a richer look. He also said specific shapes and sizes of plaques can be ordered.

Examples of plaques that have been requested from customers include:

- Photos of school sports teams

- News articles specific to a company’s achievements

- Employee of the month plaques

- Chamber of commerce groups

- Years of service awards

- Retirement plaques

- Any event that you want a lasting record to remain for future generations

Whether you are a returning customer to our Metal Photo/Dye Sublimation Department or a new one, be assured we will offer the same quality services, but at a new location!