DuraTech Takes Another Step Forward with Automated Screen Production

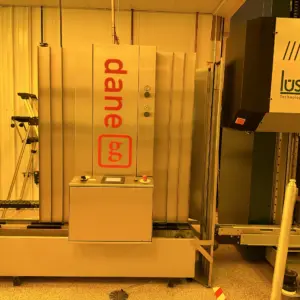

We have recently taken a big leap forward in the world of screen production with our addition of the Lüscher JetScreen! LT. This machine is considered to be one of the best models available for automated screen production. We purchased the Lüscher JetScreen! LT in December of 2021. By August 2022, we had it fully automated with the Dane system. Since then it has brought numerous benefits to our Pre-Press Department.

Why the Lüscher JetScreen! LT?

The Lüscher JetScreen! LT was brought to Pre-Press for its capacity and opportunity for less screen handling. This has resulted in significant time-saving – approximately 25% – when paired with the Dane system. The machine comes equipped with 128 lasers, making the screen production process much smoother and more efficient.

Investing in the future

Before the Lüscher, the screen production process experienced more imperfections and scratches in the film positives, and saw more cases of dirt on the film, glass and exposure unit. With the Lüscher, these problems have become a thing of the past. We’re experiencing less pinholes and better registration from screen to screen, resulting in better quality screens. The Lüscher’s computer-generated images also minimize human error, ensuring that every screen is of the highest quality.

The Lüscher is also capable of producing better and smaller line definition, making it an excellent choice for the production of high-quality screens. The Lüscher has made the screen production process smoother and more efficient, resulting in better quality screens that meet our high standards.

Our investment in the Lüscher JetScreen! LT has been a wise one. It has brought numerous benefits to us, including a reduction in time, less human error and improved screen quality. The Lüscher has become an integral part of our screen production process and has helped us to provide our customers with products of the best quality.

Why is automated screen production so important to you?

There are several reasons why we invest:

- Increased Efficiency: Automated systems such as the Lüscher and Dane combination can work 24/7 without the need for breaks, thus increasing the overall efficiency of the production process. This leads to increased productivity, reduced waste and faster production times – all benefits we can pass on to our customers.

- Improved Consistency and Quality: Automated systems are able to perform the same task with precision and consistency, which leads to improved product quality and fewer defects. Less labor is expended reworking mistakes and issues.

- Cost Savings: Automated systems can often perform tasks faster and more efficiently than humans, leading to reduced labor costs and lower production costs.

- Improved Safety: Automated systems can perform dangerous and repetitive tasks, reducing the risk of injury to workers. Preparing screens involves the use of various chemicals and the Lüscher lessens the exposure of our Team Members to those chemicals.

UPDATE – On March 20th, DuraTech had the privilege of hosting esteemed visitors from Germany. Specifically, Joernn Flottmann and Roland Schmitz, who represent two of the most prominent Pre-Press and Screen Making companies in Europe. Their specialization lies in the production of large screens, and they came to witness our unique set-up featuring the Lüscher and in-line Dane unit. It’s worth noting that DuraTech is the only company in the world to boast of such a configuration.

Joining them was Doug Shilling, the owner of Shilling Graphics, a Galion, Ohio-based company that solely focuses on Pre-Press and Screen Making. Shilling Graphics deals with both large and small screens.

David Eisenbeiss, the owner of Kissel + Wolf GmbH, KIWO Inc., and Ulano Corporation, also joined the tour. He’s known for his expertise in Emulsion, and we purchased our Lüscher and Dane equipment through KIWO.

During the tour, Peter Johnson, President of DuraTech, led the guests through all the departments at DuraTech, handing them off to Lee and Jordan, Team Leaders of our Pre-Press Department. Lee and Jordan handled the Pre-Press portion of the tour, and all three visitors were thoroughly impressed with every aspect of DuraTech’s operations, including the high level of cleanliness we maintain.

After the tour, we received this wonderful email from David Eisenbeiss: