In Partnership with CareWear, DuraTech’s at the Forefront of Wearable Medical Technology

The first wristwatch was made for Countess Koscowicz of Hungary by the Swiss watch manufacturer Patek Philippe in 1868, making it arguably the world’s first modern wearable technology.

If you’re wondering why this post begins with such a random piece of trivia – rest assured that it is relevant to today’s topic – wearable technology; specifically, photobiomodulation therapy and DuraTech’s role in helping to bring this new medical technology to market.

What is photobiomodulation?

Previously known as low level laser therapy, photobiomodulation (PBM) is a medical treatment that applies low-level lasers or light emitting diodes (LEDs) to the surface of a person’s body to relieve pain and accelerate the healing process. It’s a proven, non-invasive alternative to traditional treatments for pain and inflammation, such as opioids. PBM is used in the treatment of low back and neck pain; headaches; soft tissue injury such as contusions, muscle strains, ligament sprains, tendonitis and arthritis; and for accelerated recovery from exercise.

With the acceleration of the adoption of digital health technologies due to COVID19, patients are now able to obtain medical devices from their caregivers for at-home treatment that help to maintain and improve outcomes. Today, with the advent of wearable medical device companies like CareWear, patients can fit PBM into their everyday life while clinicians can remotely monitor utilization and outcomes within their care plan.

With the acceleration of the adoption of digital health technologies due to COVID19, patients are now able to obtain medical devices from their caregivers for at-home treatment that help to maintain and improve outcomes. Today, with the advent of wearable medical device companies like CareWear, patients can fit PBM into their everyday life while clinicians can remotely monitor utilization and outcomes within their care plan.

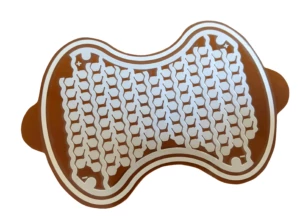

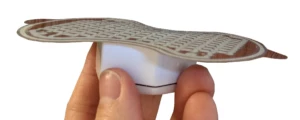

With more than 67 patents on its technologies and processes, CareWear offers effective PBM self-care with the first wearable, wireless, FDA-registered LED light patches for patients and athletes to use at home, on the road, in the clinic and even the athletic training field (more than 110 professional sports teams use CareWear patches for their injured athletes.)

“My partners and I have a history of taking effective, clinically-based medical devices, like light and electrotherapy, and figuring out how to turn them into wearable technology that can be provided to patients for use in their home under the supervision of a medical practitioner,” said Dr. Chris Castel, CEO and CTO for CareWear.

DuraTech manufactures CareWear patches

Medical device manufacturing is one of the fastest growing industries DuraTech serves. Our applications, including silicone keypads, overlays/appliques, in-mold decorating (IMD) and in-mold electronics (IME) have been used in diagnostic, detection and patient monitoring systems; control unit displays, handheld systems, hospital beds and surgical tools. And now, PBM wearable therapy.

“We supply various components, like the printed lights, and DuraTech manufactures our patches,” Dr. Castel said.

A closer look at the manufacturing process reveals some fascinating facts. For example:

Registration tolerances for each of the multiple layers that make up a single patch is plus/minus 3/1,000th of an inch – the width of a human hair.

Registration tolerances for each of the multiple layers that make up a single patch is plus/minus 3/1,000th of an inch – the width of a human hair.- DuraTech has established a zero-rejection rate in assembly of CareWear patches – a rare accomplishment for any manufacturing process.

- Heat and ultra-high photonic energy are used to literally print conductive epoxy paste onto specific points to bond two plastic circuit boards. Photonic energy is used because melting the conductive metal contained in the epoxy requires a temperature that would melt the plastic circuit boards, too. “The objective is to flow the printed metal particles in fractions of a second so that the thin film substrate is not affected by the heat of that event,” said Michael LaFebrve, Printed Electronics Development Engineer at DuraTech. “You pulse photonic energy in nanoseconds to eliminate the buildup of resonant energy. It’s absolutely the future of printing and it’s where DuraTech is heading.”

The future is bright for wearable PBM therapy

Wearable PBM therapy applications promise benefits beyond tissue healing and pain reduction, Dr. Castel said, including acne treatment and wrinkle reduction. Furthermore, “We just presented at the 2021 Photobiomodulation Conference that PBM kills the H2-N2 virus,” he said. “While it’s not the coronavirus that’s the source of the pandemic, it’s close, and that’s very exciting.”

Another exciting development is a patient’s ability to renew an acne patch prescription with the simple touch of a cell phone to the patch’s controller. “That’s the forefront of telemedicine,” Dr. Castel commented.

“We’re honored to be CareWear’s contract manufacturer in this cutting-edge adventure of wearable PBM technology,” said LeFebvre. “Not only do the patches offer convenient, effective treatment for numerous medical conditions, they are non-invasive, making them safer for the patient than other medical treatments. They also don’t use harsh chemicals that can irritate skin the way that many acne treatments do, and they come with very little packaging – no bottles, no caps or boxes that go directly to waste. Protecting our environment is a core value at DuraTech.”

For more news about the exciting future of printing, subscribe to our blog and be the first to get the latest updates.