Metalphoto®

DuraTech creates custom Metalphoto® solutions

What is Metalphoto®?

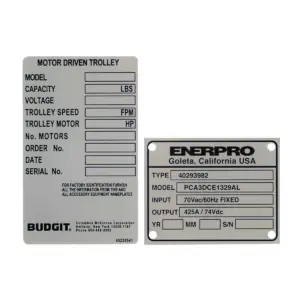

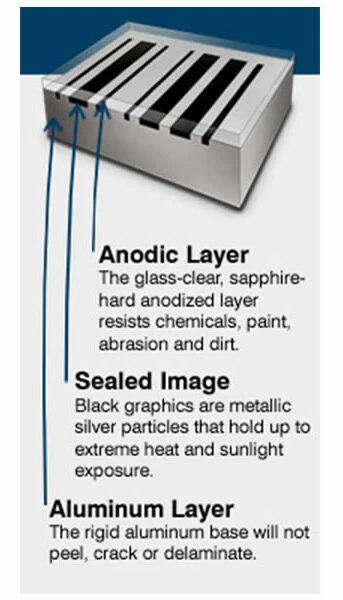

DuraTech is a convertor of Metalphoto® – photosensitive anodized aluminum. Also referred to as photo anodized aluminum, Metalphoto® has been the “go-to” option for durable labels, nameplates, equipment panels and more for more than fifty years. The Metalphoto® silver halide image is permanently sealed within the anodic layer. This makes it virtually impervious to chemicals, heat, abrasion, salt spray and UV. Metalphoto® meets an array of commercial, government and military specifications including MIL-STD-130N for Department of Defense UID data matrix bar code applications.

Are you creating a part with information on both sides? Metalphoto® can be two-sided and is a great option for a durable part, like rulers, window decals or identification plates. The process to print on both sides is the same and is available in 0.032”, 0.039”, and 0.063” thicknesses.

Metalphoto® is exceptionally durable

Metalphoto® photosensitive anodized aluminum combines extreme durability in harsh environments with a high-quality, long-lasting appearance. These nameplates and labels function perfectly for years, maintaining their original appearance under many challenging conditions including extreme heat, humidity, long term exposure to weather, UV and other outdoor conditions, salt spray, abrasion, industrial solvents and chemicals.

In outdoor uses, Metalphoto® has a 20 year guarantee. Guarantee is for gold, silver and black color only, other colors can last up to 5 years. Note that gold and silver cannot exist on the same part. The entire piece is dipped, which is what gives it the gold color, and cannot remain silver. Metalphoto® lasts a lifetime indoors.

Adhesives for Metalphoto®

If you’re looking to add adhesive to your Metalphoto® part, it’s important to find the right one. What you’re adhering to, the thickness of your plate and environmental factors will determine the adhesive needed. Traditional adhesives like 3M’s 467MP and 468MP Transfer Tapes are used with metal. However, 3M’s 9472LE is best for low surface energy applications. To prevent galvanic reactions in marine environments, 3M’s VHB5925 is a great option.

It is an option to punch holes or spaces for mechanical fasteners if adhesive is not the right fit for your part.

An ideal material selection for production requirements ranging from small to high volume

Metalphoto® makes an excellent material choice for short and medium run production requirements or when a large volume of unique or one-of-a-kind parts are required. Panels, nameplates and labels may be produced quickly and economically.

When Long-Lasting Performance Counts Choose MetalPhoto® for Your Parts.

Note: Users must test Metalphoto® products in the specific environment anticipated. Metalphoto® does not warrant performance of its materials in any environment.

*Includes Sunfast and Classic Gold Products.

Metalphoto® Fast Facts

Finishes

- Matte: Non-Reflective; Recommended for Linear and 2D Data Matrix Bar Code Labels and Applications Requiring a Non-Glare Surface.

- Satin: Semi-gloss; Medium Reflectance; Grain Direction Light but Apparent (Mill Finish Grain); Widely Specified for Nameplate, Signage and Equipment Panel Applications.

- #4: Course Brushed Finish; Grain Direction Very Apparent; Resembles #4 Stainless in Appearance.

- Gloss: Highly Reflective: Mirror-Like Appearance. Limited to 0.020″ thickness.

Applications

- Nameplates

- Panel Fronts

- Variable Information Plates, Linear and 2D Data Matrix Bar Code Labels

- UID Labels

- Data Plates

- Indoor and Outdoor Signage

- Wiring Diagrams & Schematics

- Plaques & Awards

Fastening options

- Adhesive

- Mechanical fasteners

Lifetime

- Outdoor: 20 years with gold, silver or black. Up to 5 years in other colors.

- Indoor: Will last longer indoors since it is not exposed to harsh environments and UV light.

Sizes

- 10″ x 12″

- 12″ x 20″

- 20″ x 24″

Spec or custom size sheets also available.

Performance characteristics

Extremely durable. Resistant to:

- Chemicals

- Abrasion

- High heat

- UV

- Outdoor weathering.

Thickness

- .003″

- .005″

- .008″

- .012″

- .020″

- .032″

- .063″

Material

Photosensitive anodized aluminum sheets.