Membrane switches

DuraTech creates custom membrane switch solutions

Need custom membrane switches for your product? At DuraTech, we are custom membrane switch manufacturers. For more than 45 years, we’ve worked with industries like medical, appliance, automotive, aerospace, computer and electronics, industrial and more to manufacture the custom membrane switches our customers need.

We understand it can be a challenge to decide on the right membrane switch to control your electronic device. Our ISO-certified facilities can provide on-site assistance with engineering the correct membrane switch or keypad construction for your application, including the graphic overlay combination to make your product user ready.

Our custom-built keypads include:

- Flex Copper or Silver Etched

- Silicone Rubber

- Printed Circuit Board (PCB)

- Touch Screens

- DuraSwitch

Your membrane switches can withstand repetitive use and exposure to cleaning chemicals by adding a hard-coated anti-microbial film that incorporates Microban®.

Membrane Switches 101

Here’s a bit of background on membrane switches and how they’re used.

What are membrane switches?

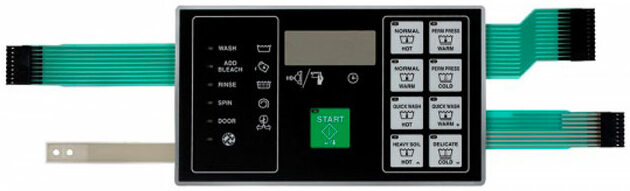

A membrane switch is an electrical switch assembly that uses contact or pressure to open or close a circuit. The main function of a membrane switch is to allow a person to press a button on a graphic overlay and achieve a desired effect in a piece of electrical equipment or machinery.

What are the components of a membrane switch?

The switches are composed of several different layers of materials that can be customized to fit your specific design and operating characteristics. However, no matter the design or function, there are a few primary components that can be found in all membrane switches:

Graphical overlay

This is the top layer of the membrane switch in which you will find digitally or screen-printed keys, buttons or other indicators. This is the layer that shows the operator what they are pressing — think buttons on a microwave or an air conditioner panel.

Spacers

Spacers are usually placed between circuits and the overlay to make sure the circuit is not activated without intent. In other words, they ensure the button only registers when it is intentionally pressed.

Circuit

The circuit is what makes a membrane switch operational and controls the electronic device. These are operated via conductive or dielectric inks to alert the system when a button is being pressed.

Adhesives

Adhesives are used in membrane switches to both attach the entire assembly to the end product, and to attach the graphical overlay layer to the circuit layer. The adhesive is crucial to ensure the membrane switch stays attached to the product, and performs as intended throughout its lifetime.

What are some examples of membrane switches in industry?

Membrane switches are common, necessary technology and can be found just about anywhere. Most all of us have come upon, used or seen membrane switches in our everyday lives, whether or not we know what these vital components are. Here are some industries that typically use membrane switches to make their products safer and more user friendly, and a short explanation about how they’re used.

Medical

Membrane switches are used throughout the medical industry on products such as blood pressure monitors, dialysis machines, communication devices, scan and testing equipment, glucose meters and much more. Membrane switches are lifesaving guides to product operation!

Home appliance

From microwaves to air conditioner panels, membrane switches can be found throughout the home. Other examples include panels on ovens, dishwashers, refrigerators, washing machines and dryers.

Retail

Whether it be card readers or general cashier setups, membrane switches can be found in nearly every point-of-sale system on the market.

Industrial Equipment

Membrane switches have a vast usage in the industrial sector. From equipment such as commercial floor scrubbers and other cleaning machines, to industrial test, measurement and diagnostic equipment such as electronic test equipment, membrane switches are prevalent in a number of different industrial areas.

Exercise Equipment

Nearly every piece of cardio equipment inside of a gym operates with a membrane switch. Stationary bikes, stair steppers and treadmills are some of the most common devices, and some newer weightlifting designs and prototypes are starting to utilize electronic interfaces and membrane switches.

What are the advantages of membrane switches?

Membrane switches provide a host of benefits to nearly every industry, and can be customized to fit a number of needs. These include:

Membrane switches provide a host of benefits to nearly every industry, and can be customized to fit a number of needs. These include:

- Membrane switches have an extremely long lifespan.

- Membrane switches significantly reduce tooling costs and assembly time.

- The integral multi-layered design seals your device from harsh environments, moisture, airborne substances like pollen, dirt/soil and other factors that could interfere with the membrane switch function. Due to the flat nature of the design, membrane switches allow for quick and easy cleaning and sanitization.

- Any graphic overlay or decorative applique can be integrated onto the membrane switch, allowing for plenty of customization opportunities.

- Various features can be added to the switch including anti-microbial materials, tactile and non-tactile button options, as well as the inclusion of audio, embossing, backlighting, back panels and ESD/EMI shielding.

Why DuraTech?

DuraTech is an expert in printed electronics (PE), in-mold structural electronics (IMSE®), in-mold decorating (IMD), graphic overlays, labels, nameplates and insulators/gaskets.

Featured Product

Autotex® Antimicrobial Film

Autotex® AM, or Antimicrobial is a unique hard coated polyester film incorporating Microban® antimicrobial protection. The Microban® technology is incorporated into the Autotex® AM textured hard coat and the film surface. The technology works 24/7 to inhibit the growth by surface contamination on the treated surface. The result is a film that stays hygienically cleaner and fresher longer.

Benefits

- Embedded antimicrobial technology for cleaner communal surfaces.

- Flexible for 5 million actuations

- Extremely durable and resistant to scratching, scuffing, chemicals and solvents

- Excellent color clarity when printed

- Tough and highly durable but tactile to touch

- Low gloss textures that are absolutely consistent across the film web

Typical Applications

- Surface protection for cleanliness of critical areas

- Kitchen equipment touch controls

- Customer touch (HMI) kiosks

- Point of sale (HMI) registers

- Tables and Counter Tops

- Door Access Panels

- Medical Devices

- Gym Equipment

- Shops and Restaurants