The Future of Printed Electronics: Screen Printing

We all do it: touch a piece of glass to dial a phone number, access information, perform a function or instantly connect with someone via text. Anyone who owns a smartphone (which is all of us) is so accustomed to interacting with technical glass through capacitive touch that we expect the same experience with every panel we encounter. And screen printing helps make it all happen.

We all do it: touch a piece of glass to dial a phone number, access information, perform a function or instantly connect with someone via text. Anyone who owns a smartphone (which is all of us) is so accustomed to interacting with technical glass through capacitive touch that we expect the same experience with every panel we encounter. And screen printing helps make it all happen.

As Michael LeFebvre, Printed Electronics Development Engineer at DuraTech, likes to say, “Contrary to popular opinion, screen printing is not a dying art! What most people don’t know is that every piece of technical glass – every single piece – has been screen printed. Nobody put a brush or roller to it. Nobody sprayed it. But every piece is screen printed along with additional vapor deposited coatings on the front to resist oils and moisture.”

Welcome to the future of screen printing. Here at DuraTech, we’re helping to shape the future of the industry.

Sleek user interface made possible with thin film functionalization

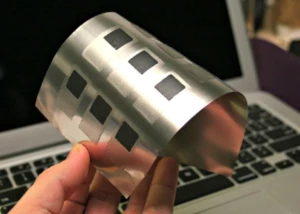

Sleek, human-centric user interface has become predominant in contemporary product design, and screen printing is keeping pace. Touching a surface to make something work, for example, requires screen printing conductive silver nano particles onto extremely thin film – the thickness of only two human hairs – made of plastic, glass, metal or some combination of these materials. We refer to the process as thin film functionalization.

What’s more, with our best-in-class in-mold structural electronics (IMSE®) manufacturing process that combines screen printing functional inks with injection molding; once the film is printed, it can be molded, converting it from flat, two-dimensional material into three dimensions.

“It’s one thing to screen print on a surface that’s flat,” LeFebvre said. “But we’re now looking at that surface (glass) and bending it. Of course, it can’t just be a regular piece of glass. The stuff we’re experimenting with is one millimeter or less thick so it can be bent without breaking.”

Functional thin films enable manufacturers to produce thinner, lighter products. “The automotive industry, for instance, is always pushing technology. They want to know how the components contained in that first inch behind the dash can be reduced as much as possible,” said Paul Hatlem, DuraTech’s Sales Manager.

Functional thin films enable manufacturers to produce thinner, lighter products. “The automotive industry, for instance, is always pushing technology. They want to know how the components contained in that first inch behind the dash can be reduced as much as possible,” said Paul Hatlem, DuraTech’s Sales Manager.

To support the auto, appliance, medical device, consumer electronics and other industries in their quest for thinner, lighter user interface components, DuraTech leverages materials technology in new and existing products. “Take inks,” Hatlem said. “Ink manufacturers are continuously improving them with more conductivity and flexibility. If we can get higher conductivity from printed silver inks, for example, we can print finer lines to carry the same amount of electrical current, which results in thinner, smaller parts.”

Smart labels

Have you ever walked into a fast food restaurant and used a contactless ordering system to place your order? How does the server, whom you haven’t met, deliver your meal directly to your table? How did they know where you were sitting?

It’s not magic – it’s screen printing. DuraTech prints smart labels used by one of America’s largest fast food enterprises. Those labels contain NFC tags, small RFID antennae and table numbers, all of which feed part of a larger technology platform designed to cut down the time between when your food is ready and when it arrives at your table. Once a customer scans their mobile device over the smart label and orders their food, the staff behind the scenes not only see what they want to eat, they also see the table number.

“NFC tags aren’t new, but printing the table number in the label brings about a whole new process,” Hatlem said.

LeFebvre added: “That process is now starting to be applied in wayfinding systems. Imagine you’re in a large hospital and told to go to radiology. You’ll have an RFID badge that lights up and points you in the right direction. A little green arrow will show up that’ll tell you to turn left, then right, and so on. The system will be reacting to internet connections installed in the ceiling tiles. It’s the perfect application for this new screen printing technology.”

Sensors

Because they augment safety in myriad situations, pressure – or human detection – sensors represent a large and growing area for screen printing. Think of the light or alarm that activates after someone sits in the front passenger seat of your vehicle and doesn’t buckle up. In the world of screen printing, a similar application is being applied to mats for use in hospital and nursing home beds, manufacturing and restaurant floors and more.

“The manner in which we’re producing pressure sensors is unique,” Hatlem said. “We print a conductive ink onto a large, thin film – one you usually wouldn’t use in screen printing but that we’ve had a great deal of success with – to produce floor mats that the customer uses to determine if someone is standing in a restricted area.”

New developments in pressure sensors are leading to even more elaborate applications. LeFebvre projects that with certain types of printed sensors, you’ll be able to determine the weight and stride length of the person who’s standing on a mat, which can lead to deducing their height. “You start daisy-chaining this information together and you could identify who was standing on that mat and at what time. This kind of analytics can be applied to security systems for financial institutions, for instance,” he said.

Security bags

Another unique application for functionalizing thin film plastics is to screen print a continuous pattern inside a bag. Because the pattern is made from conductive inks and carbon nanotubes, the bag itself can send an electronic signal to indicate if the bag has been opened or tampered with.

At DuraTech, we print and fold an extremely thin, white film into such a bag. A functional adhesive is applied so, once it’s sealed, it’s impossible to open and reseal it. In other words, the bag has to be “defeated” or destroyed in order to open it. And the only person authorized to do that is the receiver.

“Let’s say I’m shipping you $5 million in diamonds,” LeFebvre explained. “You and I both want that bag to be as secure as possible. With the bag we’re printing, if someone takes a pair of scissors and cuts into it, a timer immediately stops and the bag sends a blue tooth signal that it’s been defeated – that the bag has stopped working at a precise time and GPS location. A bag like this can have a wide range of shipping and delivery applications – vaccines and other pharmaceuticals, legal documents, you name it.”

Printed batteries

The growing world of flexible electronics will be fueled by printed batteries. Starting with a thin functional plastic film, DuraTech is researching and developing a process to print primary use batteries with magnesium and zinc pastes separated by a very thin membrane that allows ions to pass through the barrier to create an electrical charge. These batteries, which will be printed in sheets with layers sandwiched together, will power consumer products such as cameras, personal entertainment devices and exercise monitors.

Additionally, “No lithium will be involved in the printing of these batteries,” LeFebvre said. “We’ll be using common, every day, green materials because we need to know that, whenever we manufacture something designed to be thrown away, we’re not adding to the world’s problems. DuraTech takes this very seriously.”

Green, printable power generation beyond batteries promises a bright future for screen printing, Hatlem believes. “I foresee that we’ll be printing a clear ink on a clear substrate that, once it’s applied to the windows in your house, you’ll be able to leverage the sun to generate electricity.”

Healing injuries with printed LEDs

Wearable therapeutics, specifically light therapy, is yet another cutting edge technology that DuraTech is working with. Using micro LED particles suspended in ink, photo biomodulation patches fabricated with thin, flexible materials send light waves into the body’s capillaries to keep blood flowing, thereby reducing pain and preventing bruises from forming.

Wearable therapeutics, specifically light therapy, is yet another cutting edge technology that DuraTech is working with. Using micro LED particles suspended in ink, photo biomodulation patches fabricated with thin, flexible materials send light waves into the body’s capillaries to keep blood flowing, thereby reducing pain and preventing bruises from forming.

“The manufacturing process requires the use of very, very thin films with almost-unheard-of tolerances of less than 10 microns,” LeFebvre said. “With our value added assembly capability, DuraTech coverts all of the constituents comprising these patches, ensures that they are functional, pulls them out of the array and prints the gel that applies the patch to the body.”

From healing with light to aiding forensic investigations and expediting restaurant operations, screen printing is the new “secret sauce” that’s making our lives safer and more functional. “This is such an exciting time for our industry,” LeFebvre concluded.

To stay up to date on DuraTech’s latest developments in printed electronics, follow us on LinkedIn.